The German gunmaker is now making shotguns for the covertside. Jonathan Young goes undercover to investigate just how they do it.

“So, Mr Bond, let me show you round our installation. You understand, of course, that we will never allow you to reveal all our secrets.” And with that warning, or something vaguely close, I was shown into the Blaser shotgun factory in Isny, Germany and forbidden to shake hands with the robots. Most modern factories have automata and that includes gunmakers, though one imagines they are named Henry and James at Holland & Holland and Purdey. Mostly they are static CNC machines with automotive processes, solid members of the workforce but not ones to enliven a grey Monday morning. But at Blaser (though this cannot be revealed), there is a chirpy robot who bustles up and down the aisles selecting parts for his sedentary colleagues who steadily put in their 24 hours a day cutting and spark-eroding, working to an accuracy of 0.01 of a millimetre – an accuracy checked by laser. “Any sharp edges are then smoothed here,” said Alexandra Baur, leading me to a tumbling machine filled with ceramic stones. “They stay in there for about one-and-a-half hours until they are perfect. And you know how important perfection is for us Germans,” she added, without a trace of smile. Baur is Blaser’s head of PR and plays the Teutonic joke well. And the company’s striving for order and efficiency can verge on the humorous. Where else, for example, would a drinks dispenser be adapted so that each human worker can find the right item in-stantly? But this seeking for perfection is also rather noble in itself and gratifying for the customer. Who wouldn’t want a rifle or shotgun that was as well made and reliable as possible?

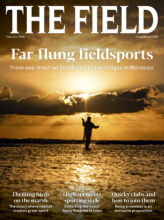

Above: the F3 Game standard

Below: the F3 Vantage Super Sport

Take the barrels. They are made in-house from a non-stainless, standardised NATO-certified steel for small arms. The cylinders are cold-hammer forged, a process that Blaser shotgun pre-fers because “it does not tamper unduly with the steel’s molecular structure”. The barrels are then plasma nitrided against corrosion.

Blaser’s barrels are made in-house from a non-stainless, standardised NATO-certified steel for small arms

The rifles come in 30 calibres, with .308 and 30-06 being most popular in Germany. Unlike a traditional bolt-action, which takes four movements to eject and load, the Blaser shotgun has a straight-pull action that requires two: you pull the bolt back and forwards. As a result, it’s easy to keep the rifle fully mounted and the scope’s cross-hairs continuously on the quarry, the beauty of which was obvious when Baur took me to Blaser’s “cinema”.

This is actually a firing range, using live rounds at targets projected on a 15-metre screen. “What would you like to start with? Boar or buffalo?” asked Baur. ‘OK, boar it is,” nodding to her colleague in the control booth. I chambered a round and the lights went out but instead of the pa-pa-pah pa-pa-pah of the Pearl & Dean ads there came a-grunting and a-squealing as a troop of wild boar me-andered out of a forest fringe, halted on catching my wind and looked directly towards me. I lined up on the biggest – boom! – then its lieutenant – boom! – and managed a third before the boar scattered off the screen. “Not bad,” said the range officer, “have a look.” The hits on the screen are recorded on the computer, so you can see exactly where each round was placed. “Two of those are stone dead but the third, I’m afraid, will be a job for the dogs. Want another go or shall we try the Cape buffalo?” This shooting cinema is the first I’ve seen but it’s used abroad as part of the hunting exam that many Europeans, including the Germans, have to pass. A number of sessions is required before a licence is issued but they’re so much fun that’s not much of a hardship.

BLASER BREAK TIME

“Now you can see how quick our rifles are, it’s time we looked at the guns but not before we have lunch,” said Baur, leading me to the senior executives’ canteen, a Hansel and Gretel wooden chalet next to the stark factory buildings. On the way, every colleague called out “Mahlzeit!” “It means ‘enjoy your lunch’,” said Baur, “and it’s the traditional German greeting around noon. We usually eat together at the canteen because it gives us a chance to catch up with what’s going on elsewhere in the business. And a good lunch is important, too.”

I thought of how lunch is now usually taken in the UK – munched at the desk before a hot computer – and then remembered an English friend telling me about his time working in Munich. “One night I’d stayed late to finish off some work and my boss came back into the office to collect something he’d forgotten. ‘What are you doing still here?’ he asked and when I explained he told me that in Germany you’re expected to do all your work in work hours, not outside them – and if you can’t manage to do that you’re probably in the wrong job.”

It was a reminder, if needed, that German industry is as much about a particular vision as mechanical efficiency – though the latter is always to the fore at Blaser, as underlined by the maker’s F3 shotgun action.